Boiler | Classification of Boilers

Boiler is a closed steel shell in which steam is generated from water by combustion of fuel. The steam produced in the boiler in widely used working fluid in thermal power plants to produce power . It is also used for processing in chemical and sugar factories , bleaching in cotton and paper mills and to drive locomotives and ships .

As a working fluid in power plants , the steam has the following advantages .

- high heat capacity

- can easily be condensed and evaporated

- work of compression is very small

Definition and function of a boiler

In simple terms boiler may be defined as a closed vessel or shell in which steam is produced from water by combustion of fuel . The water is pumped into the boiler at operating pressure . The heat of flue gas vaporise the water to form steam . The steam formed is passed into the steam space which is directly above the water surface . The steam collected above the water surface is always wet . If superheated steam is required , then the wet steam is passed into superheater where it is dried and finally superheated . To improve the thermal efficiency , the feed water is passed through an economiser where its temperature is increased before entering into the boiler . Thus feed water is supplied to the boiler at a high temperature . Hence , less heat is required to raise the steam . This results in a higher efficiency

Steam generator

A steam generator is a combination of apparatus for producing heat and transferring the available heat to water to generate steam at desired pressure and temperature . The basic elements of steam generator include boiler drum , superheater , economiser and air preheater . It may be noted that the boiler is a part of a steam generator where water at saturation temperature is converted to steam at same temperature . Thus in the boiler only phase change occurs from liquid to vapour at constant pressure and temperature . However , the terms boiler and steam generator are used interchangibly.

Function of boiler

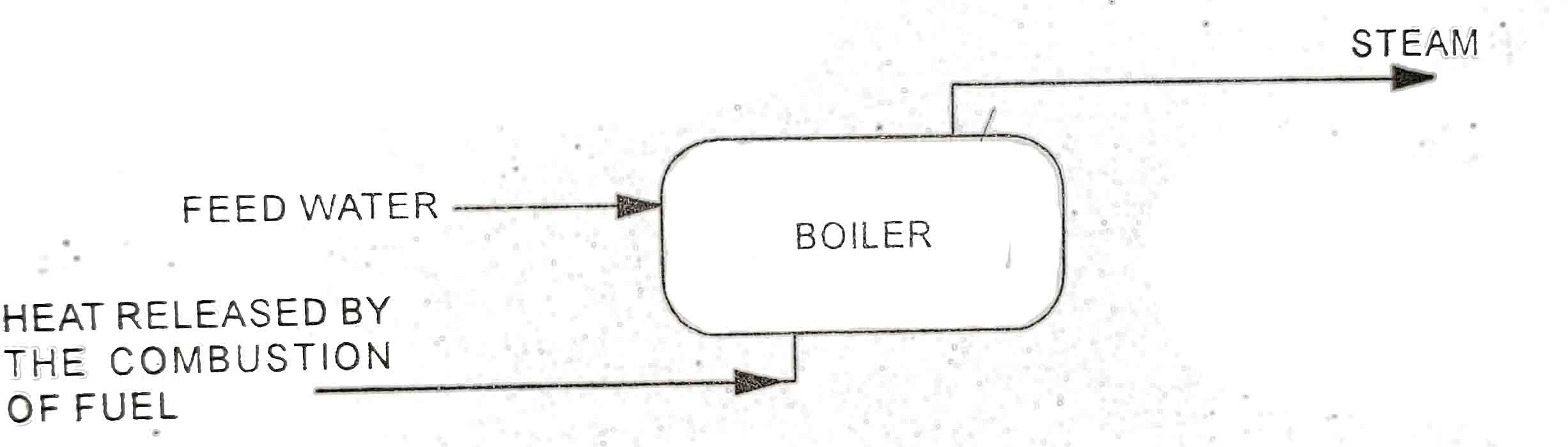

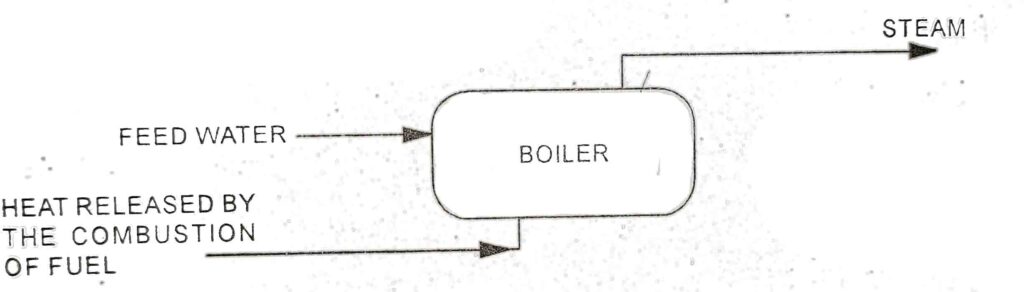

The function of a boiler is to provide controlled release of heat in the fuel , and efficient transfer of heat to the feed water to produce steam at the desired pressure and temperature . Fig . 3.1 illustrate the essential function of a boiler . The steam can be supplied from the boiler at constant pressure by maintaining the steam generation rate and steam flow rate equal .

Classification of boilers

According to the content in the tubes , the boilers may be classified as

- Fire tube boilers

- Water tube boilers

Fire tube boilers

In fire tube boiler , the hot gases pass through the tubes surrounded by the water from which the steam is generated . Followings are some example of fire tube boiler.

- Simple vertical boiler

- Locomotive boiler

- Cochran boiler

- Cornish boiler

- Lancashire boiler

- Scotch boiler

Water tube boilers

In water tube boiler , water is made to pass through a large number of tubes over which the hot gases flow . Most modern boilers are built as water tube boilers. Followings are some example of water tube boiler.

- Babcock and wilcox boiler

- Stirling boiler

- Yarrow boiler

Further classification of boilers based on

- Location of furnace

- Internally fired boilers – Furnace is located inside the boiler

- Externally fired boilers – Furnace is located outside the boilers

- Axis of the shell

- Vertical

- Horizontal boiler

- Circulation of water

- Natural circulation – No pump is required; circulation of water is due to difference in densities

- Forced circulation – Uses pump to force water

- Service to which they are employed

- Stationary boilers – Boilers installed in power plants and industrial units

- Mobile boilers – Marine boilers and locomotive boilers

Components of Boiler

- Pressure Gauge – This indicates the pressure of the steam in the boiler.

- Water Level Indicator – This indicates the water level in the boiler The water level in the boiler should not fall below a particular level otherwise the boiler will be overheated and the tubes may bum out

- Safety Valve – The function of the safety valve is to prevent the increase of steam pressure in the heller above its design pressure . When the pressure increases above design pressure , the valve opens and discharges the steam to the atmosphere . When this pressure falls just below design pressure , the valve closes automatically . Usually the valve is spring controlled .

- Fusible Plug – If the water level in the boiler falls below a predetermined level , the boiler shell and tubes will be overheated . And if it continued , the tubes may burn , as the water cover will be removed . It can he prevented by stopping the burning of fuel on the grate . When the temperature of the shell increases above a particular level , the fusible plug , which is mounted over the gratemelts and forms an opening . The high – pressure steam pushes the remaining water through this hole on the grate and the fire is extinguished

- Blow-off Cock – The water supplied to the boiler always contains impurities like mud , sand and , salt Due to heating , these are deposited at the bottom of the boiler , and if they are not removed , they are accumulated at the bottom of the boiler and reduces its capacity and heat transfer rates . Also the salt content will goes on increasing due to evaporation of water . These deposited salts are removed with the help of blow off cock . The blow – off cock is located at the bottom of the boiler as shown in the figure and is operated only when the boiler is running . When the blow – off cock is opened during the running of the boiler , the high – pressure steam pushes the water and the collected material at the bottom is blown out . Blowing some water out also reduces the concentration every 5 to 6 hours of working for few minutes . This keeps the boiler clean .

- Steam Stop Valve – It regulates the flow of steam supply outside . The steam from the boiler first enters into an ant – priming pipe where most of the water particles associated with steam are re moved

- Feed Check Valve – The high pressure feed water is supplied to the boiler through this valve . This valve opens towards the boiler only and feeds the water to the boiler . If the feed water pressure is less than boiler steam pressure then this valve remains closed and prevents the back flow of steam through the valve .

Selection of Boiler

The following factors are to be considered while selecting the boiler for a particular use.

- Operation pressure

- Steam generating rate

- Quality of steam required

- Availability of floor space

- Fuel to be used

- Nature of load on the boiler

- Initial cost

Requirements of a good boiler

Steam boiler must be reliable and efficiently transfer heat released by the combustion of fuel to feed water . The primary requirements ( characteristics of a good boiler ) of a boiler or steam Steam boiler must be reliable and efficiently transfer heat released by the combustion of fuel generator are :

- It should be capable of producing maximum amount of steam with minimum fuel consumption .

- It should occupy less space and should be light in weight .

- It should be capable of quick starting and should rapidly meet the fluctuation of load .

- It should be safe in working i.e. , the water must be contained safely and steam must be safely delivered at desired condition . Thus it should satisfy the safety regulations of Boiler Act .

- It should be economical , and require only little attention during operation .

- All parts should be easily accessible for inspection and repairs .

The two important factors which dictate the selection of boilers are operating pressure and steam rate. Fire tube boiler can be used only upto 25 bar and 10 tons/hr capacity. Above this range water tube boilers have to be used.

FAQ

What are the different types of boiler.

Simple vertical boiler, Locomotive boiler, Cochran boiler, Cornish boiler, Lancashire boiler, Scotch boiler, Babcock and wilcox boiler, Stirling boiler, Yarrow boiler

What are the different types of fire tube boiler

Simple vertical boiler, Locomotive boiler, Cochran boiler, Cornish boiler, Lancashire boiler, Scotch boiler.

What are the different types of water tube boiler

Babcock and wilcox boiler, Stirling boiler, Yarrow boiler

What is fire tube boilers

In fire tube boiler , the hot gases pass through the tubes surrounded by the water from which the steam is generated .

What is water tube boilers

In water tube boiler , water is made to pass through a large number of tubes over which the hot gases flow . Most modern boilers are built as water tube boilers.